TU Delft

client

deliverables

Material Studies, Form studies & Conceptual Model

in short

The inspiration for this project was an old patent of a lemon squeezer. The exercise was to analyze this patent as a design team and translate it into a modern design without the use of electricity. After analyzing the patent and the general concept we assigned each functional part of the patent to a team member. This way we could focus on going in depth, but still keep track trough working in the same place. During this process we worked closely to make sure that every component was compatible with the others. The final result was a compact

ideation

Getting creative.

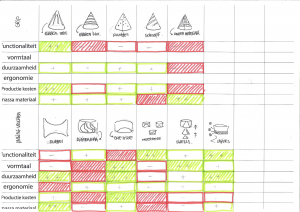

As a team we did several creative sessions in which we brainstormed trying to interpret the patent’s parts from a different perspective. For most of the parts the functionality was a leading for the shape. When we were questioning ourselves if the design could be more compact to fit in a small kitchen we came up with the idea to remove the lever and use a lid instead. This forced us to rethink the location of the spindle. In the original design it is located in the top cone. Since there was no more space available for the spindle in the lid we decided to use the lower cone for the spindle. So by pressing the lemon on the lower cone it would rotate. To confirm if this would work we measured how much force was needed to squeeze a lemon and if the body weight of a person was enough to do so.

embodiment

Towards feasibility

During the embodiment we divided the different parts individually. I methodically approached the design of the lid to create different shapes and decide which was most appropriate. In doing so we had to keep in mind the form language of JosephJoseph which was all about keeping the design simple in shape and function. Part of this project was also about learning how to make a design ready for production. To secure it’s feasibility we specified the different aspects like dimensions including tolerances, material use and part connections by communicating with several experts. Then we determined the most suitable production methods for the different part depending on the design, the material and the desired texture. In choosing the materials we considered their price, durability and sustainability to match the core values of JosephJoseph.

presentation

The Final Design

To get a feel of the shape and size we made a mockup from paper, wood and foam. To determine the final looks of the product we did a color study to determine the best color combination. In doing so the goal was to create an outstanding but well balanced color scheme with a typical JosephJoseph look. To finish off we did a complete cost price indication, adviced on a marketing strategy and designed the package in the style and guidelines of JosephJoseph.